Wastewater Treatment Solutions

Tangent engineering offers a complete range of wastewater treatment solutions for issues arising due to industrial and domestic wastewater pollution. Technology-driven solutions are provided by selecting a suitable technology. Our expert team has vast project experience in working with various types of industries. We guarantee a stable and economical treatment process for many types of wastewater according to the nature of the industrial production. The range of wastewater treatment solutions includes customized solutions based on proven and quality-oriented technologies and applicable for multiple kinds of industrial wastewaters such as pharmaceutical, oil & gas, textile, dyes, paint, food and beverages, chemicals, and many such as. Our non-industrial wastewater solutions are applicable for institutes, commercial and residential communities, hotels and hospitals, etc.

The products are mainly used for meeting government norms for emitting wastewater quality, reuse and recycle of wastewater, and minimizing freshwater demand. This resulting in cost savings for the purchase and treatment of freshwater, reclamation of energy or by-products from the waste stream, and zero liquid discharge. Our products help industries in controlling polluting factors arising due to Fats, Oils, and Grease (FOG), Total Suspended Solids (TSS), acidic or alkaline pH, Biological/Chemical Oxygen Demand (BOD/COD), Phosphorous (P, P₄) Fluoride (F), Metals (Cadmium, Copper, Chromium, Nickel, Zinc, etc.), Volatile Organic Compounds (VOC) & Many Others.

- Customized units , concept to commissioning turnkey solutions

- Meets stringent quality norms as per state and central PCB, NGT discharge criteria

- Automatic, semi auto and PLC based control units

- Multiple options for construction, type, technology and sourced material.

- Suitable for indoor- outdoor locations, units can be placed below ground

- Portable, containerized units options available

- Effluent Treatment Plant ( ETP)

- Domestic wastewater/ sewage treatment plant ( STP)

- Oil and sediments removal

- Solid liquid separation

- Membrane based wastewater tertiary treatment

- Membrane bio reactor

- Ultra filtration, ozone, oxidation treatment

Effluent Treatment Plant ( ETP)

- Preliminary and primary treatment: Includes solids and oil removal.

- Physical-chemical treatment using coagulation and flocculation

- Biological treatment using aerobic or anaerobic biological treatment

- Filtration , Disinfection Technology

- Customized solutions

- Pilot treatability arrangements

- Use of proven technical methods

- Combination of treatment unit operations

- Use of reputed components and equipment’s

- Hotels & resorts, community kitchens, canteen waste

- Hospitals, Pharmaceutical units

- Textile, engineering, manufacturing, laundry units

- Dairy, food products, confectionary, food processing. Meat processing units,Chemicals, fertilizers, dyes and other industries.

Effluent Treatment unit with available options for material of constructions as follows

- Mild steel with epoxy painting (MSEP)

- Mild steel with FRP lining

- CS (carbon steel) with epoxy painting

- FRP (Fiberglass reinforced plastic)

- PP FRP

- Civil tanks

Starting from min 5 KLD to any as per customized design , can be offered as per requirement

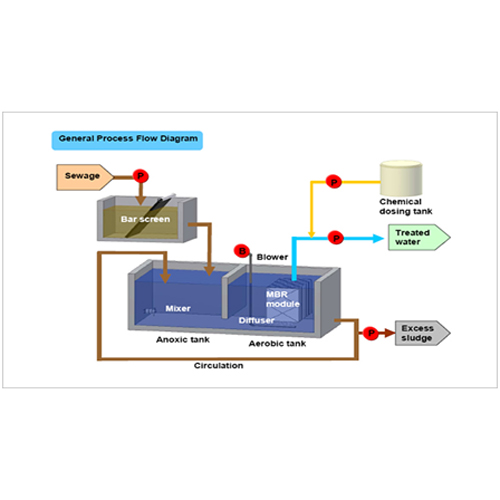

Domestic Wastewater/ Sewage Treatment Plant ( STP)

Sewage Treatment Plants are designed for the treatment of the wastewater generated in communities such as residential and commercial colonies, hotels, hospitals, institutes, factories, etc. The process involves the methodology of removing toxic materials that may otherwise cause serious damage to the environment. The treated water outlet is an environmentally safe fluid waste stream; which can either be reused for many applications or drained into the sewer without causing damage to the environment.

- Moving Bed Bio Reactor (MBBR)

- Sequencing Batch Reactor (SBR)

- Membrane Bio Reactor (MBR)

- Upstream Anaerobic Sludge Blanket (UASB)

- Advanced Oxidation

- Compact & robust design with long life,

- Easily transportable worldwide

- “all-in-one” single tank unit.

- Any Capacity

- High quality treated water

- minimal land usage (smaller foot print)

- Use of reputed components

- Easy start-up & rapid installation

- Design based on specific application.

- Modern control system with MCC or PLC based operating system.

- Low maintenance.

- Low power consumption.

- Easy operation no high skilled labour required.

- Low & odourless operation

- Can be installed in basement area with less height

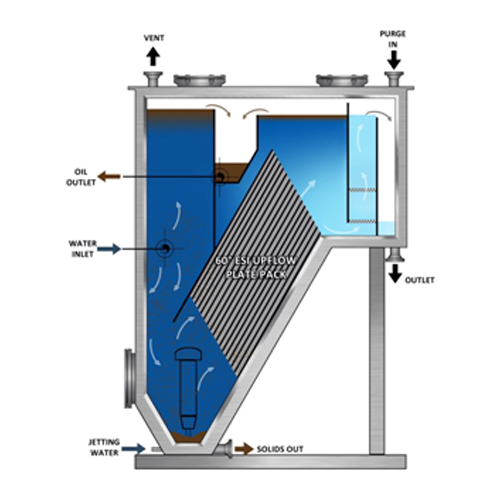

Oil and Sediments Removal

The effluent containing oil and grease (O&G)) causes ecology damages for aquatic organisms, plants, animals. It is equally, mutagenic and carcinogenic for human beings. The conventional techniques remove oil and grease using skimming tanks and oil and grease traps in treatment plants. The oil layer is extracted out by skimmer units. The oily wastewater is found in two types i.e. free-floating and emulsified. Floating oil has a definite separation of oil and water layers due to its immiscible nature however in the case of emulsions, the mixing is miscible. Hence treatment units are segregated for both types of wastewater.

- Customized design as per nature and type of oil

- Available in multiple combinations and material of construction

- 95% efficient in removal of oil and >80% removal of solids

- Comprehensive complete treatment units.

Solid / Liquid Separation

Suspended Solids are major part of pollutants in any wastewater. Solids from the wastewater are removed by following techniques

- Manual/ mechanical bar screens

- Screw type screen

- Rotary mechanical drum screen

- Settlers- Gravity, Tube settlers, Lamella settler

- Clarifiers- mechanical Clari-flocculators, High rate contact clarifiers

- Chemical dosing for coagulation and flocculation, flash mixers

- Sludge Thickeners

- Drying beds

- Filter press

- Belt press

- Centrifuge units

Membrane Technology for Wastewater Tertiary Treatment

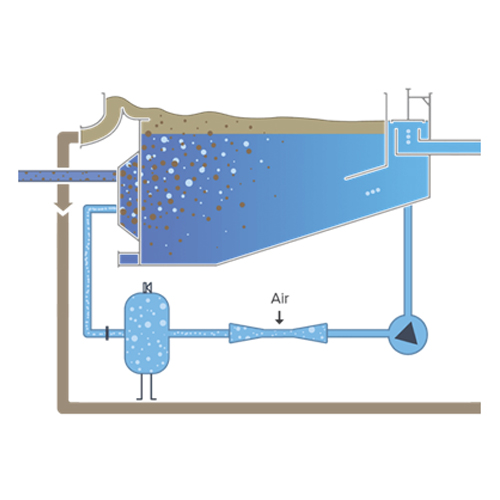

MBR systems allow the complete physical retention of bacterial flocs and virtually all suspended solids within the bioreactor. As a result, the MBR has many advantages over conventional wastewater treatment processes. These include small footprint and reactor requirements, high effluent quality, good disinfection and odor control capability, higher volumetric loading and less sludge production.

MBR systems are most convenient option for up gradation of old conventional wastewater treatment units without adding up of new construction. MBR’s also provide benefits of upgrading water quality for reuse purpose and ultimate goal of zero liquid discharge.

Membrane Filtrations

- in terms of low turbidity, TSS, BOD, and bacteria

- Ability to absorb shock loads

- Treated water can be directly reused for many applications

- Eliminates environmental hazard of surrounding due algae growth

- Low hydraulic retention time and hence low foot (area) requirement

- Automated operation, minimum chances of human error

- Due to high MLSS system can be upgraded to high capacity.

- Membrane barrier separates bacteria and virus up to log 4

- Tangent Provides complete MBR process solution along with pre and post treatment.

- Complete design solution and process backup with experienced in-house engineering team.

- Represents multiple membranes brands and providing selection meeting to customer requirements.

- MBR process works on automation Tangent offers complete automation solution for your MBR system

Polishing Wastewater Treatment

The final stage of wastewater treatment known as tertiary or polishing treatment. The aim of tertiary wastewater treatment is to raise the quality of the water to reuse standards, or to meet specific requirements around the safe discharge of water. This stage is essential for removal of pathogens, removal of color, odor, trace solids which ensures that treated wastewater meets desired standard and safe for reuse purpose.

The stages of polishing treatment are

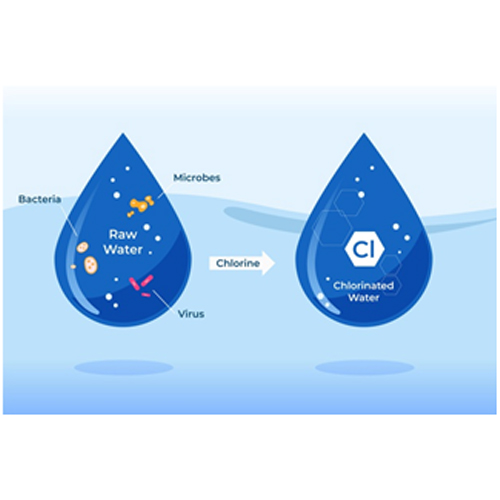

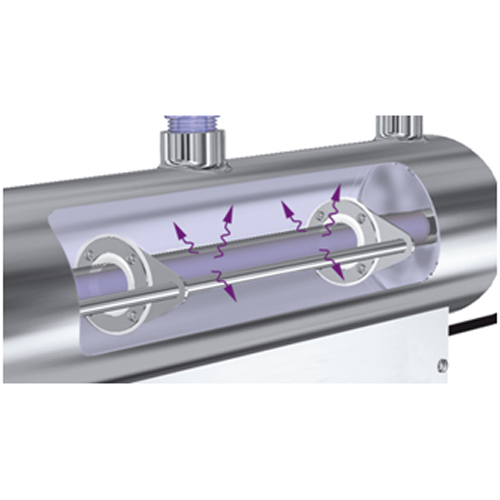

Disinfection: The disinfection is used to eliminate bacteria, viruses and pathogens which may lead to create health hazards. Technologies used for disinfection purpose are