Industrial and Domestic water solutions

The Industrial and Domestic water division offers comprehensive water treatment solutions to customers seeking reliable results from their water process. It includes water sampling, system design, equipment supply, system integration, chemical supply, and remote diagnostic reporting. Our goal is to streamline and optimize the treatment and management of water resources for our clients ensuring the performance and water utilization are maximized.

The product manufacturing process and industries require a clean water source and per degree of process need for production, manufacturing, and many more allied uses. Water is required for nearly every step of production across a multitude of different industries. According to the product being manufactured and the raw water quality as per source, a special level of treatment technologies is provided. Quantity of water requirement also varies as per production and hence to meet quality with production cost selective line of treatment is considered.

Drinking water contains water molecules and a large variety of other substances. Being universal solvent other substances easily dissolves in water. Water that falls to earth during rain showers dissolves substances, particles, and gasses such as oxygen, which can be found in the air. Contaminants that are present in the air also dissolve in rainwater. When surface water flows on earth it also dissolves several different substances, such as sand particles, organic matter, microorganisms, and minerals. Water that settles into the ground and becomes groundwater, often contains large amounts of dissolved minerals, as a result of contact with soils and rocks. Human activities, such as agriculture and industrial waste, and sewer water discharge cause several pollutants to enter the water.

- Customized , Compact and Efficient Systems

- Proven Trusted

- Use of modern technology

- Reliable High Performance

- Designed by qualified engineering team

- Conformance to quality norms for output and system engineering

- Industrial process water treatment

- Drinking water treatment

- Membrane based water treatment: Reverse osmosis, Ultra filtration, Nano filtration, Micro filtration

- Filtration and ion exchange

- Demineralization, Deionization

- Disinfection

- Iron and metal removal

- Arsenic, fluoride removal

Industrial process water treatment

- Process applications

- Hygienic use

- Sterile use

- Cooling tower and Boiler use

- Desalination & dematerialized water

- Solids removal technologies

- Filtration Technology

- Membrane Technology

- Resin Technology

- Disinfection Technology

Drinking and domestic use water treatment

- Conventional physio-chemical clarification treatments

- Modern filtration and Membrane based treatment systems

- Water softening, hardness, TDS, color removal

- Disinfection, pathogen removal Heavy metals

- Arsenic, fluoride, Boron removal

- Treatment solutions to meet Drinking water norms as per BIS , WHO, EPA

- Modern technology with lower energy requirements

- Quick installation and low maintenance

- Customized solutions based on type of contamination

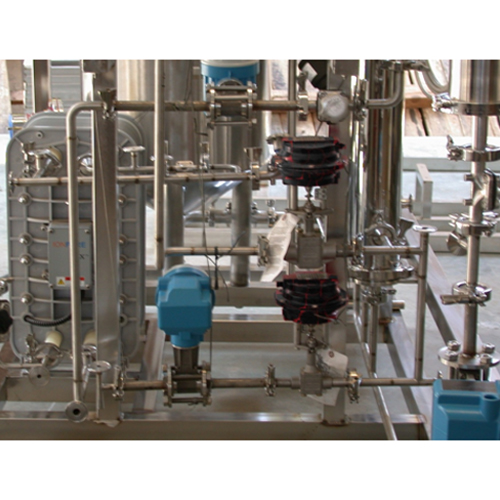

- Tangent offers skid mounted & non skid systems with multiple options for Skid MOC, Make of components and level of automation.

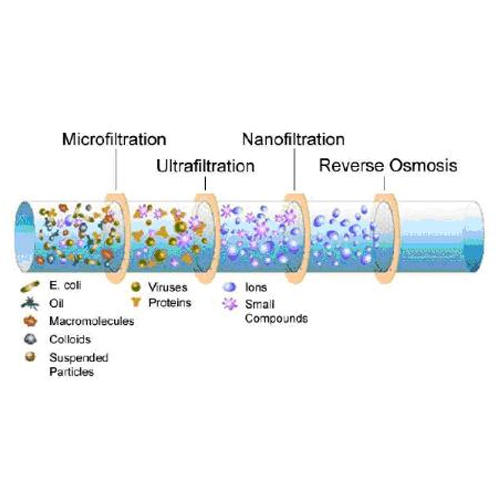

Membrane based water treatment

- Ultrafiltration (UF) – approx 0.01 µm pores: impermeable to small colloids and viruses

- Nanofiltration (NF) – approx 0.001 µm pores: impermeable to dissolved organic matter (DOM) and divalent ions

- Reverse osmosis (RO) – effectively non-porous: impermeable to monovalent ions

- Electro deionization

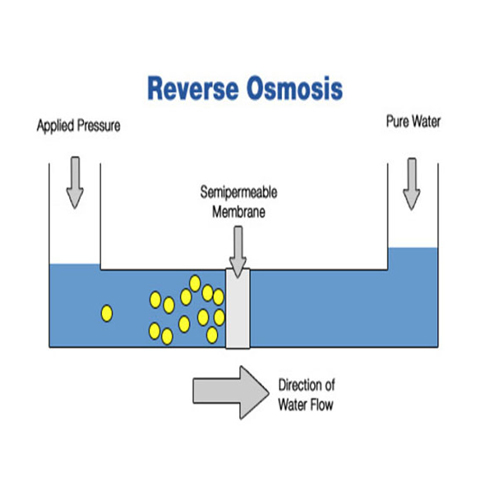

Reverse Osmosis System

- Tangent provides, Automatic and Semi-Automatic systems which are user friendly and easy to operate.

- Use of multiple sensors within the system for means of smooth operation & preventive safeguarding of system are provided to ensure the permeate quality meting stringent norms.

- Metallurgy of Contact and Non-Contact Parts is selected as per the process requirement.

- Tangent offers skid mounted systems with multiple options for Skid MOC, Make of components and level of automation.

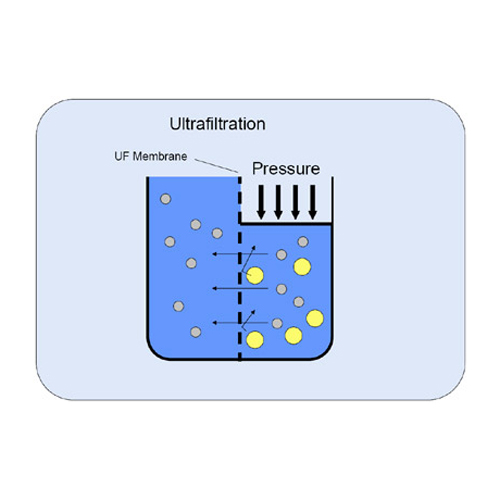

Ultra filtration System

Ultra filtration is a membrane-based technology to remove suspended solids, Colloidal matter, High Molecular Weight Substances, bacteria, and viruses from various feed water sources. UF can achieve a low and consistent silt density index (SDI) and is often used as a pre-treatment for reverse osmosis using surface water, seawater, and biologically treated wastewater as a feed source.

Ultra filtration (UF) is recognized as a low-pressure membrane filtration process, it is usually defined to be limited to membranes with pore diameters from 0.005µm to 0.1µm. When the source water is passing through the filter under a trans-membrane pressure provided by gravity or a pump, the suspended solids particles, bacteria and most viruses can be removed, and the use of chemicals, capital, and operating cost can be reduced.

- Excellent permeate quality

- Product SDI typically less than 1

- Removal of virus, and bacteria

- Removal of microbiological matter

- Removal of colloidal matter

- Colloidal Silica Reduction

- Safeguarding downstream Reverse Osmosis (RO) performance & life

- Consistent product water quality irrespective of changes in feed water quality

- Tangent offers skid mounted systems with multiple options for Skid MOC, Make of components and level of automation.

- Pretreatment to RO system (brackish and seawater applications)

- Purification of surface and well water for portable applications

- Filtration of industrial water

- Zero liquid discharge recycle and reuse

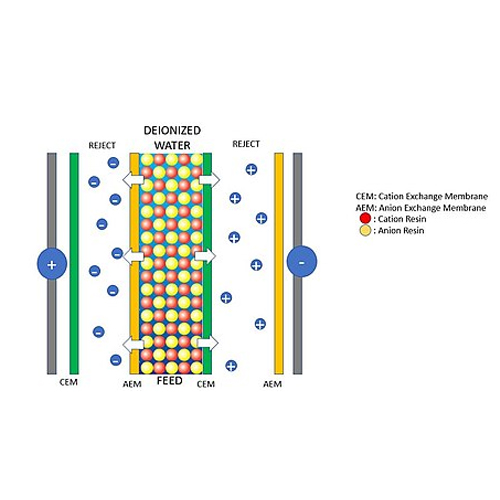

Electro-Deionization

- Consistent conductivity (<1us-cm)

- No chemical Regeneration required

- Low Operating Cost

- Can be sanitized

- Auto Dumping in case inlet conductivity exceeds

- Automatic/Semi-automatic operation.

- Sensors to monitor/ Safeguard the system.

- Tangent offers skid mounted systems with multiple options for Skid MOC, Make of components and level of automation.

- Reuse of residual water in food and beverage industry Chemical production

- Biotechnology Electronics

- Cosmetic Laboratories

- Pharmaceutical industry Boiler Feed Water

- Removing dissolved ions up to 5-17 M?-cm, TOC No involvement of harmful chemicals for regenerating resin

- Designed to deliver reliable, low-cost ultrapure water solutions with up to 18 MOhm-cm resistivity.

- Systems designed to effectively remove residual salts and ionizable aqueous species like silica, carbon dioxide, ammonia

- Operating without chemicals, these systems are designed to achieve 95% water recovery

- Reduce energy and operating expenses

- Reduction in environmental waste

- Stable continuous performance with lower operating costs

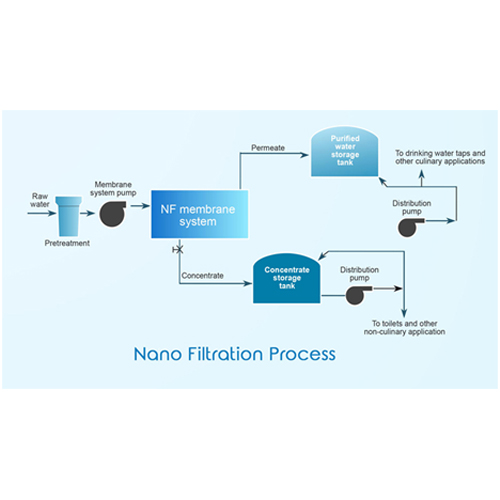

Nano Filtration System

- Low Operational costs.

- Automatic/Semi-automatic operation.

- Sensors to monitor/ Safeguard the system.

- Viruses, organic elements, and valence ions are removed from the hard water.

- It is an effective way of softening the hard water.

- The membrane has very tiny holes therefore, most molecules cannot pass through.

- Tangent offers skid mounted systems with multiple options for Skid MOC, Make of components and level of automation.

- Polishing and quality enhancement of conventional water treatment

- water softening and hardness removal and removal of synthetic organic matter in water with low total dissolved solids

- NF membranes are also used for the removal of natural organic matter from water, especially tastes, odours and colours, and in the removal of trace herbicides from large water flows.

Filtration & ion exchange

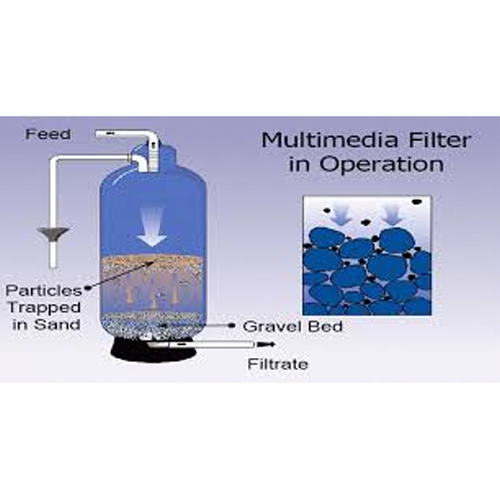

Multi Grade Sand Filter

- Effective for Suspended solids removal

- Low Maintenance and operational Costs.

- Easy to operate

- Less wastage of water

- Feed Water can be used for backwashing the filter

- Tangent provides Multi Grade sand filter in various sizes and metallurgy FRP, MS-EP, MS-FRP, MS-RL, SS 304, SS 304L, SS 316) as per client and process needs.

- Automatic or manual

- Drinking Water treatment for surface and ground water sources

- Filtration of clarified water.

- Water used in chemical processes.

- Filtration process in Industries.

- Used for pre – treatment for membrane systems.

- Swimming Pool Water Filtration.

- Pharmaceutical Production processes.